MSEI CASE EXAMPLE

MSEI was contacted to investigate an alleged chemical leak suspected of causing irritation and burning sensations to the skin and eyes of multiple workers. These workers, from diverse trades, had been carrying out general remodelling work inside a retail unit of a building constructed in 2004.

MSEI conducted a series of tests, the results of which presented no elevated concentrations of volatiles or particulate matter. Later, olfactory observations indicated no abnormal odours.

No complaints were received from neighbouring units, within the building. The property owner confirmed that no other work was being conducted elsewhere in the building and there appeared to be no indication of any sources of potential contaminants. As a precaution, the site was cleaned and aerated, and work continued. Subsequently, more workers complained of similar burning sensations and reddening of skin and eyes.

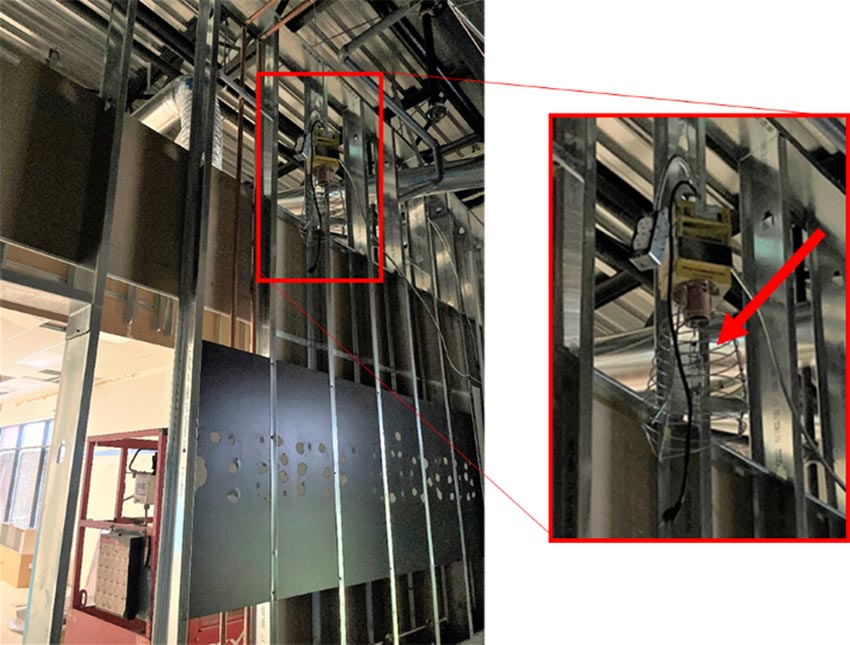

MSEI received information which indicated that a temporary work light, inactive during MSEI’s initial investigation, was defective. MSEI examined the light, and it was found to be a high-intensity discharge fixture, specifically with a metal halide lamp (source). This type of light, known as a high bay light, is commonly used in warehouses and factories, and are designed to be located at a ceiling height of approximately 20 to 45 feet (6 to 14 metres).

The arc tube, from which the light radiation is emitted, appeared to be intact. The protective glass outer jacket (or shield), that would act to filter harmful ultraviolet (UV) radiation emitted by the lamp was absent, broken. Remnants of the outer jacket could be seen at the base of the source. The welded cage housing the lamp, designed to prevent any damage to the outer jacket, was intact and appeared undamaged.

Photo: Demonstration of the type and location of the metal halide bulb light fixture. The absence of the outer shield is indicated by the red arrow.

Mapping of worker activity versus the occurrence of health complaints showed that all the reported cases of skin and eye irritation coincided with work being conducted in the section of the building where the light was located. Further investigation revealed that the light had been active during the renovation work and that workers had been in proximity, and sometimes directly next, to the fixture.

MSEI was informed that no medical intervention was sought by the workers and no official documentation from any authority of the events or injuries was available.

Documentation

The U.S. Centre for Disease Control (CDC) documents two cases of photokeratitis (a painful eye condition caused by exposure to UV radiation) which affected multiple individuals attending sporting events at gymnasiums in Philadelphia. Significantly, 242 individual cases were associated with a 2011 event, where symptoms included burning eyes, red eyes, tearing eyes, and foreign body sensation.*

The U.S Food & Drug Administration (FDA) website details a notice entitled Ultraviolet Radiation Burns From High Intensity Metal Halide and Mercury Vapor Lighting Remain a Public Health Concern and indicated as current as of February 05, 2018. **

The FDA notice states that the glass outer shield of a metal halide bulb (or lamp) filters the intense and harmful UV radiation which would otherwise be emitted from the lamp without the shield. If the glass is damaged or absent, the short wavelength UV radiation may cause symptoms which include burns to the eyes and skin, headaches, nausea, and problems with vision.

*https://www.cdc.gov/mmwr/volumes/65/wr/mm6511a4.htm

**https://www.fda.gov/radiation-emitting-products/alerts-and-notices/ultraviolet-radiation-burns-high-intensity-metal-halide-and-mercury-vapor-lighting-remain-public)

Conclusion

As this light was confirmed to be functional despite the absence of an outer jacket, we are of the opinion that potentially harmful UV radiation was likely emitted during its use and that any worker in proximity to the lamp and without the appropriate personal protective equipment would have been exposed to potentially harmful UV radiation.

Precautions

- Lights should be regularly inspected for damage.

- Bulbs with cracked glass outer shields should NEVER BE USED.

- Damaged cages should be repaired.

- Lights located in work areas that are at risk of being physically damaged should be relocated or replaced with fully enclosed fixtures.

- Workers should be reminded that such lights may continue to work even when damaged.

- Workers should be educated as to the dangers of UV radiation from damaged metal halide lamps.

The FDA recommends replacement of fixtures with open or wire cages with enclosed fixtures and that lights within open fixtures be replaced with self-extinguishing type bulbs.

Further reading

Studies that establish a link between UV radiation exposure from metal halide lamps and medical complaints include:

Mazzuckelli LF, MacDonald PD, Langley RL, Howell RJ. Erythema and conjunctivitis: investigation of an outbreak in a school gymnasium caused by unintentional exposure to ultraviolet radiation from metal halide lamps. J Occup Environ Hyg 2007;4:D46–9.

and

Kirschke DL, Jones TF, Smith NM, Schaffner W. Photokeratitis and UV-radiation burns associated with damaged metal halide lamps. Arch Pediatr Adolesc Med 2004;158:372‑6.

For any further questions regarding this topic, do not hesitate to contact your specialist:

Ian Harvey, B.Sc. (Hons)

Scientific Expert

Senior Project Manager

514-249-6576

iharvey@msei.ca